We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Heavy Duty Coiler – PC 3000

$0.00

1, 2, 3, and 5 HP AC Vector Variable Speed Drive System to maintain line tension and automatically synchronize speed of

coiler with speed of process line.

SKU

PC3000-003-001

Part Number:

PC3000-003-001

Shipping by Freight ONLYAdditional Fee for Crating/Pallet/Skid: $2,800.00

$0.00

Product Details

1, 2, 3, and 5 HP AC Vector Variable Speed Drive System to maintain line tension and automatically synchronize speed of coiler with speed of process line.

Products Overview

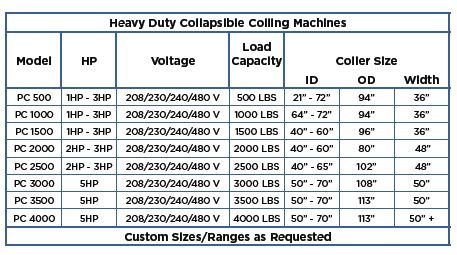

PC3000 Heavy Duty In-Line Coiling Machine.

INCLUDES:

• Coil capacities, manually adjustable expand collapse for 50”, 60”, 70” and 84” ID coils on 2” increments x 113” (Specify ID diameters required if different than listed) O.D. x manually adjustable width up to 48” wide x up to 3,000 lbs. load capacity. Note: 84” ID will be a separate set of bolt on ID pads and will still have a 113” OD

• Low profile, heavy duty structural steel frame construction with bolt-down floor flanges.

• Electric/hydraulic activated coiler expanding/collapsing feature.

• 5 HP AC Vector Variable Speed and Torque Drive System, 0 to approximately 5 RPM

• 480 VAC three phase power required.

• Zero Speed Holding

• Spring applied, electric release holding brake. Engages on power loss or e-stop.

• Potentiometer for Torque Control, Maximum speed potentiometer, and Forward/Reverse feature available on either side or both of coiler

• Pushbutton, hydraulic powered, coiler expand collapse

• Extended and reinforced I.D. pads for a rounder coil to prevent crimping.

• Paint: RP Blue with Safety Orange arms.

• Forklift base

• Manually adjustable tail clamp to allow operator to manually adjust tail clamp alignment to the pipe tail and secure tail for strapping.

• Pipe bung quick release pin. Includes holes located at each collapsing arm to allow operator to easily attach pipe bung tail to coiler.

Models/Options

Standard Features

- 1, 2, 3, and 5 HP AC Vector Variable Speed Drive System to maintain line tension and automatically synchronize speed of coiler with speed of process line.

- HD structural steel frame construction with bolt-down floor flanges

- Inner arms fully adjustable for coil widths as specified with “T” handle bolts

- Hydraulic activated coiler expanding/collapsing feature with joystick control

- May be designed for the Take-Up over the top or underneath the coiler.

- Forward/Reverse

- Extended and reinforced I.D. pads for a rounder coil to prevent crimping

- Forklift base

Write Your Own Review

No question found!