Submitted by:

DON MOREAU

Senior VP, Sales & Marketing / Industrial Division

5101 S. Council Rd., Suite 100, Okla. City, OK 73179

O 405.609.3346 C 405.245.8840

[email protected]

1. Can you provide a brief overview of your company and the products/services you'll be showcasing at the event?

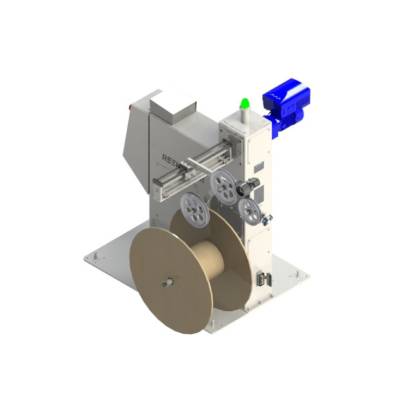

Reel Power Industrial is the industry leader in designing and manufacturing precision winding equipment to reel, coil, and spool flexible products. Reel Power provides valued customers with “World Class” application-specific solutions which lower their buying risk, while enhancing their overall manufacturing profitability by improving process throughput, while lowering the cost per unit. We will have equipment on display at the Reel Power booth along with literature and information on our comprehensive line of reeling, coiling and spooling products.

2. What recent trends or developments in the industry are you most excited about, and how do your products/services align with them?

General trends in the wire industry and industrial industries/infrastructure affect our business, we see low voltage wire segments to continue with slow growth over the next few years, while the data center segment which is dominated by Copper Wire and Fiber Optic Cable continues to be booming, and it will continue to do so for the next 5+ years. The electrification space which includes Power Grids, Transmission needs, along with EV’s continues at a much slower pace than the Data Center opportunities.

a. Specific trends in the Market Place include:

- Complete Automation – All industries are requiring enhanced automation to reduce the need for workers on a specific line and improve overall throughput.

- Safety Needs – Companies are continuing to be more safety conscious, with increased OSHA enforcement, high cost of litigation caused by injuries, there is an increased need to prevent injuries from occurring.

- Enhance Automation & Packaging – Machines equipped to reduce process steps, and go right to final packaging are in very high demand, as they reduce overall system costs. We offer an array of secondary operations such as banding, tying, plastic stretch wrap and labeling and our solutions can be customized to the specific application.

- Improved Processing Speeds – The faster a manufacturing system can produce, the more that it can produce, reducing unit cost, while improving overall plant profitability.

- System Integration Provider – Manufacturing companies look towards companies who can handle all their system needs “one stop shopping”, provides purchasing leverage, reducing overall system integration costs. We can integrate robots (as was recently displayed live and running at the NPE show in May), and any other equipment to provide an overall solution.

- Data processing & Knowledge Transfer – All companies want to transfer customer specific information directly to the equipment building the products, improving overall manufacturing efficiencies, reducing costs, at the same time they want information about each piece of equipment to schedule maintenance and replacement equipment events, to plan better, while improving overall efficiency.

- Provide Full-Service Mechanical & Electrical support & Maintenance – Companies who can provide all of this will be able to be partners instead of just providers, locking in long-term multi-year relationships.

Reel Power has the ability to provide all of the above, making us a unique developer and manufacturer of custom solutions in the flexible product reeling, coiling, and spooling precision winding market place.

3. Could you share a success story or case study demonstrating how your products/services have benefitted a customer?

We were approached to build three machines for an Automotive parts supplier from Canada. Their request was for an automated machine that was modular, and that could automatically change out a cartridge system. When we designed and built this particular piece of equipment, we enhanced it so that multiple size dies could be processed in one line, with a quick changeout, this eliminated the need to buy three lines, as they were able to produce all their needs through our single line of manufacturing equipment. We were able to reduce waste, while improving overall winding capability, and reducing overall lines needed and the manning of those lines.

4. Will you be conducting any demonstrations or interactive activities at the event? If so, what can attendees expect?

At this show we will utilize Audio visuals with movies to show actual machines operating with different products and showcase our overall solutions capabilities through HD videos.

5. What are your company's goals for the future, and how do you see yourselves contributing to the evolving industry landscape?

We want to continue to grow, enhance our market position as the largest winding, coiling, and spooling designer and builder, as well as offer additional winding and downstream World Class Winding Solutions & Equipment.

6. What are you most looking forward to at this year’s show?

Improve our overall Brand Recognition, while at the same time generate a strong list of candidates to call on and sell to.