We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Reel Power Industrial Leads the Way in Standard and Customized Re-Reeving Equipment - User-friendly, Convenient and Durable

Reel Power Industrial Leads the Way in Standard and Customized Re-Reeving Equipment - User-friendly, Convenient and Durable

Reel Power Industrial Leads the Way in Standard and Customized Re-Reeving Equipment – User-friendly, Convenient and Durable

Re-Reeving machinery provides tension controlled pay-out and re-spooling

for boom hoist and main lift line applications.

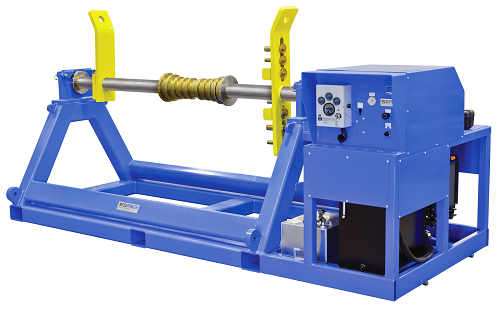

(Reel Power Int’l, Oklahoma City, OK September 5, 2017) … Reel Power Industrial Inc. sets the industry standard in Re-Reeving equipment ideal for Re-Reeving cranes, winches, hoists, and boom hoist applications that require heavy pay-off tension and take-up rewind capabilities with large, heavy ropes. These rugged units are completely self-contained, with either gasoline or diesel engine powered hydraulic systems up to and including 44 HP.

The equipment allows you to more safely change out the wire on your lifting device, by providing a shaft to store your cable on while replacing the cable, and also allowing you to apply back tension to the wire rope as it is being installed. It eliminates the need to tie the wire rope onto the back of a pickup truck and drag the wire on the ground while changing out the wire rope, which is cumbersome and may damage the wire.

The Re-Reevers come standard with a fork lift base and lift eyes, along with a hand operated pressure release valve to adjust the torque as needed. There is also a manual hand valve for speed and direction control. The slide coupling disconnect promotes easy and smooth loading as well as “free wheel” capacity.

Standard models begin at 5,000 LBs and go all the way up to and including units that are available for weight capacities exceeding 100,000 LBs . The latest Re-Reeving Series are available with customized torque capabilities and application specific reel dimensions per customer required specifications.

About Reel Power International, Inc.

Reel Power International is the parent company of three industry-leading brands: Tulsa Power®, Reel-O-Matic® and Radoil. Our product offerings are diverse, but the goal of every product is the same: To make users’ operations more efficient, productive, profitable and safe.

Standard and custom solutions. Across our three brands, you’ll find a wide range of products designed for drilling, reeling and winding operations. And if you don’t find what you need in our catalogs, we can custom-design the perfect solution for your business.

Qualified engineers behind every product. To ensure the highest level of quality and safety, all of our products are developed by degreed engineers. And each of our brand companies is backed by the most experienced engineering organizations.

A commitment to innovation and growth. As the challenges and needs of the industries we serve evolve, so do our solutions. We continue to identify challenges, design innovative solutions and manufacture quality products that decrease delays, and save time and money.

For more information visit: