What is an Up-Cut Extrusion saw?

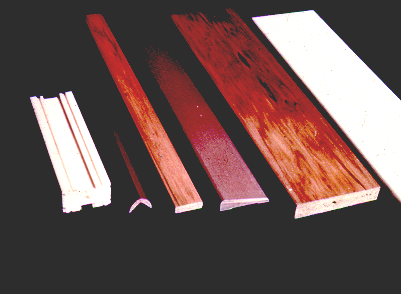

An Up-Cut Extrusion saw is a type of saw that uses a circular blade to cut through materials in an upward motion. The blade is housed inside the saw's base and is only visible when cutting. Up-Cut Extrusion saws are used for a variety of materials, including wood, plastic, and non-ferrous metals like aluminum, copper, and lead. They are often used in manufacturing operations and are known for their accuracy, efficiency, and safety.

What problem does the Up-Cut Extrusion saw solve?

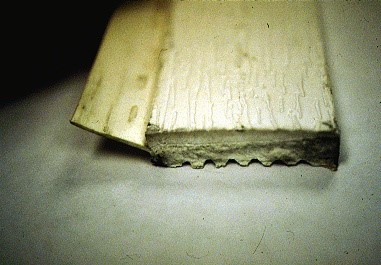

Reel Power's Up-Cut Extrusion Saw cuts rigid materials quickly and accurately. It minimizes waste. The Up-Cut Extrusion saw also reduces chipping, burrs, rough cut edges, noise, and excessive particulate matter.

What are the typical challenges in using regular saws that Reel Power’s Up-Cut Extrusion saws solve?

Typical challenges of using saws are chipping and burring, noise and particulate evacuation. Non-servo saws have cut tolerance issues. Certain materials, like rigid foams and co-extrusions, require specific saws to avoid damage. It is very important to find a balance between hardness and toughness in cutting-edge materials.

What sets Reel Power's Up-Cut Extrusion Saw apart from other products on the market?

Reel Power Up-Cut Extrusion Saw includes some unique features as standard.

Features that make the Reel Power Up-Cut Extrusion Saw stand out:

- Externally adjustable blade depth.

- Adaptable for different sizes of blades.

- The Traveling table is powered by a servo motor

- It offers variable speed cutting

- Hinged table for easy access to blade shroud and internal area

Other standard features:

- Low clamp pressure needed because of the servo table travel matches product speed before the clamp

- Variable Speed Control for saw blade

- Enhanced Chip Collection with a vacuum chip tube and sealed shroud.

- Faster product changes (external adjustments of the clamp, variable blade speed)

Ideal applications of Up-Cut Extrusion saws:

- To cut rigid profile and pipe

- To cut foams

- Long cut lengths

The technical specification of an Up-Cut Extrusion saw:

- Table moves via a Siemens Servo Motor and 32:1 Planetary Gear Reduction

- Siemens 7-inch High Resolution PLC Touch Screen Control with Recipe Management

- Fully Enclosed Blade Cavity with Above Table Stainless Steel Blade Shroud and guarding for operator safety

- Hinged table for easy access to blade enclosure and body

- 3 Hp. Saw Arbor Motor with variable speed of 2275 to 3300 RPM

- 20″ Diameter Blade and 24″ Table Travel

- Table speed up to 45 ft./min. with up to 15 cuts/min.

- 5000 Pulse Encoder and Mounting Kit

- Lockable Power Disconnect

About the blade used:

Reel Power's Up-Cut Extrusion saw has a carbide blade. It is the second toughest material, after diamond. The blade is designed to work with various materials and surface speeds. The Up-Cut Extrusion saw is adaptable to various blade sizes and can handle blades up to 20 inches in diameter.

The advantages of the servo table travel process over pneumatic:

- Improved accuracy: The servo motor ensures precise, clean square cuts.

- Reduced bending risk: Unlike pneumatic systems, it minimizes the risk of bending and angled cuts during cutting.

- Enhanced cut tolerance: Maintains higher cut tolerance, leading to more consistent quality.

- Table and product mobility: Allows both the table and product to move for optimized cutting alignment.

- Smooth cutting: The servo motor provides smoother cutting motions compared to pneumatic systems.

RPI’s traveling cutting table features

Here's a list of the features of the RPI’s traveling cutting table:

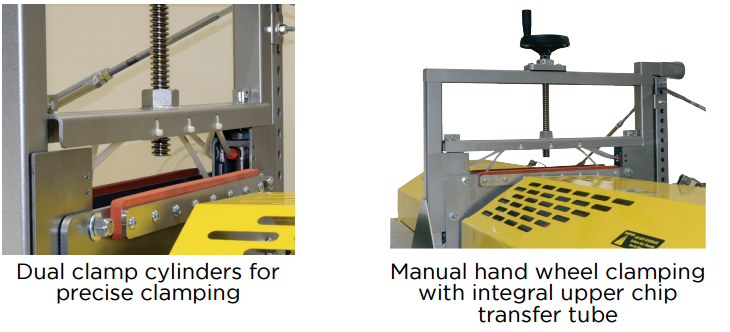

- Adjustable clamps: For enhanced control during cutting.

- Variable speed Servo motor: Allows for customizable speed adjustments.

- Pivoting tabletop: Facilitates maintenance and access.

- Hinged design: Provides easy access for adjustments or repairs.

- Accommodates different products: Can handle various product sizes and types.

- Two orientations are available: Allows flexibility in positioning for different tasks.