We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Coiling Machines

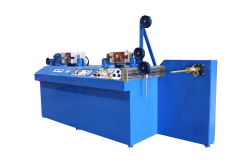

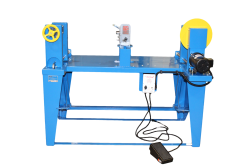

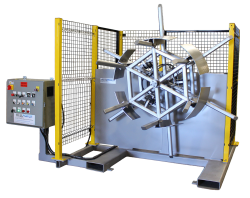

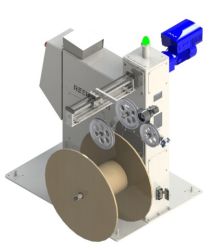

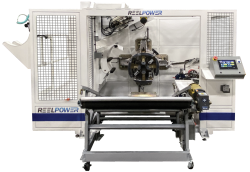

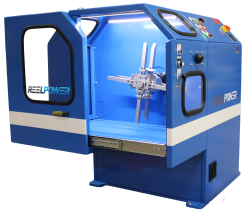

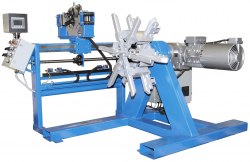

- The “Mini-Penthouse” is ideally suited for pulling material from reel racks, reel roller platforms or a pay-out cart. Also, ideal for use with an extrusion line when equipped$11,391.48Includes Mini-Penthouse Standard Features and Options with the Additional Following Features: Integral Cutter for up to 2” Diameter Material Weighted Base for$30,500.34Includes Mini-Penthouse Standard Features and Options with the Additional Following Features: 36” Diameter CT Coil Turntable with Adjustable ID Pins for Coil Payo and Center$14,465.00For increased productivity, this machine allows the operator to load or unload finished Take-up reels while unit continues its re-spooling functions. The Dual Shafted High SpeedStandard FeaturesCapacity 24” diameter x 12” wide x 150 LBs Dynamic Braking Feature V-Belt Drive Remote Safety Foot Switch Speed Control Potentiometer Illuminated1, 2, 3, and 5 HP AC Vector Variable Speed Drive System to maintain line tension and automatically synchronize speed of coiler with speed of process line.Standard Specifications1 HP SCR Variable Speed Drive, 0-70 RPM Pay-out capacity 20” to 48” dia. x 36” wide x 2,500 lbs. ROM 1700 Measurer - 1/8” to 2” dia.Manual Mini-Penthouse - Manually operated Measuring and Coiling System for flexible materials. Inculdes Stand, 1700 Measurer and coiler. See the detail$6,949.67Wire Insulation Tester WIT 101 High Speed Re-Spooler: The Wire Insulation Tester (WIT ) is powered by a 1 HP variable speed drive system providing speeds up to 1,000 ft perThe Heavy Duty Coiler is to be used with Coil Steel, Rubber Belting, Sheet Tubing, Heavy Cable and other flexible material applications.Includes the Following Penthouse Standard Features and Optional Features Available:Standard: 36” Diameter Coil Turntable with Adjustable ID Pins for CoilCoiler Options:3/8 C - Coiler 3.5” Wide X 8” I.D. X 14” O.D.3/12 C - Coiler 3.5” Wide X 12” I.D. X 21” O.D.3/16 C - Coiler 3.5” Wide X$3,290.79Custom-Designed, Automated Manufacturing Equipment for Processing Flexible Materials Standard FeaturesTakeup - 3 HP A/C Vector Variable Speed Drive Automatic 15mm AmacoilAutomated Spooling Machines are very much used in spooling wire, spooling flexible materials and much more application.A wide range of coiling equipment is available for winding material onto reels/ spools or onto coils (stretch wrapped or banded). Both on and off-line coilers areCoiler Options: 3/8 C - Coiler 3.5” Wide X 8” I.D. X 14” O.D. 3/12 C - Coiler 3.5” Wide X 12” I.D. X 21” O.D. 3/16 C - Coiler 3.5”$2,583.47Equipment BenefitsAutomatic Cut & Transfer Precision Military Winding Improved Production up to 1000 FPM Optional Automatic Stretch Wrap Lowest Maintenance No Belts,Automatic Rewind Coiler comes out with higher coil production at lower cost, greater production flexibility and increase extrusion speed up to 100% and reduce labor cost up toThe ACT System is highly flexible and reliable applicable to multiple products and applications. Now operating on and offline wire and cable, medical tubing andplasticSpecial heavy duty coiler comes with wide range coiler width varying from 4-30.It is hand operated with crank ID varyiung from 26-31. It is used for synchronizing in lineSemiautomatic coilers are a low cost alternative to fully automatic equipment. These coilers wind the product as it emerges from the extrusion line automatically followingSemiautomatic coilers are a low cost alternative to fully automatic equipment. These coilers wind the product as it emerges from the extrusion line automatically followingPrecision winding machine utilizing a common traverse to wind either spindles or coils with very high accuracy.• With 3/4” diameter machine cold roll steel, plug in style-payoff & takeup shafts • Digital stop-to-length 3100 counter with 1/64”-7/8” OD capabilities, dualDesigned to solve “light tension” profile winding challenges Extensive diagnostics make troubleshooting and failure predictions simpler Precision winding patterns,Cutter/Coiler/Binder Cuts Wire to Desired Length Binds Coil in Two Places Custom Tail Lengths for TerminationAutomatic Coiler • Allen Bradley PLC • Red Lion HMI • Automatic Feed • Automatic Cutter • Automatic Coiler • Automatic Bander • Automatic EjectManual Mobile Coiler with 3100M Measurer p/n 13650-317• 31” Turntable with 4 adjustable pins to hold coil in place. Center pin is for holding reels.• Turntable weight$1,725.00Hydraulic Power Unit for Reel Lifting and Pintle Positioning System and Inverted Auto Traverse with Adjustable Roller Guide Box for Under WindingHD-HSS Hydraulic Automatic Expand/Collapsible (Model- HD-IL-HSS753)3 HP 0-10 RPM 480 3 phase drive, hydraulic assist coiler with speed and tension control Coiler:SINGLE SHAFTED TAKE UP - LOW TENSION APPLICATIONS STANDARD FEATURES INCLUDE:Heavy gauge sheet metal cabinet 3 axis servo drive Spindle maximum weight (50lb) PrecisionLow Tension No Contact Dancer The Low Tension No Contact Dancer is designed to protect delicate & sensitive product which may be damaged or over stressed by sheaves in otherDual Shafted Tower Style Pay Off Model TSPO is a light weight, economical pay out machine that is ideal for 30-inch spools up to 15 inches wide and weighing 150 lb. or less. ItDual Shafted Tower Style Take up Model TSTU is a lightweight, economical yet sophisticated take up machine perfect for reeling product up to 1.5 in. width at rates up to 250Single Shafted Tower Style Pay Off Model TSPO is a light weight, economical pay out machine that is ideal for 30-inch spools up to 15 inches wide and weighing 150 lb. It comesSingle Shafted Tower Style Take up Model TSTU is a lightweight, economical yet sophisticated take up machine perfect for reeling product up to 1.5 in. width at rates up to 250Save warehouse space, improve internal logistics, and reduce shipping costs and product returns by producing coils of your HDPE, PP, PEX or PE-RT pipe products automatically fromSpecialized wire tester for testing harness wire utilized in aircraft, ship, automotive, and other OEM harness applications.Custom Pneumatic Powered Expand High-Speed Coiling Machine with custom Coiler 8” x 18.5” x 3.75” wideDual Spindle ”Low Tension” Take-Up Material is positively pushed onto the spool with our very "low tension” patent pending technology, preventing the profile from crushing.Heavy-duty coiling machine for heavy materialGreat for scrap-coiling applications Featured for wire rope usage and bare wireThe model SP-HDHSS757 comes with 7.5 HP ACEquipment Benefits:Automatic Cut & Transfer Precision Military Winding Improved Production up to 1000 FPM Optional Automatic Stretch Wrap Precise Tension Control LowestThe Benefits of Reel Power Semi-Automatic Pipe Coiling System: Reduce CostsOnly one operator is required to oversee the operation of two or more machines. Where coilerFull Guarding & Safety Interlocking DoorsLexan Viewing of Operations 2” Capacity Programmable HMI/PLC Measurer Tension Controlled Payoff Dual Take Up With AutomaticFor Coiling/ Re-spooling Corrugated Stainless Steel Gas Line Coils, Reels, Bands, Wraps, Ejects, Cuts, & Conveys FEATURES:Programmable recipe management Allen-BradleyCustom In-Line Dual Take-Up Coiling Machinery FEATURES:Model Shown ILHSS752-002 - Reference 38382 2 HP, 0-5 RPM, 230 VAC, 3 PH. AC Vector Precision Speed & TorqueReel Power Industrial’s custom ARC series single spindle film wrap coiler can be configured to work in-line. Corrugated coil will be film wrapped and auto ejected to customerLeaders with (PCT) Pipe Coil Technology Innovations Standard Features:Wide range of coil head adjustment Safe and ergonomic operation Automatic pipe layering AutomaticReduce Ovality and Achieve More Compact Coil Dimensions Low Ovality (LV) Technology was developed by and remains unique to Reel Power. It enables high density polyethylene pipe