We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Pipe Coiling and Reeling Machines

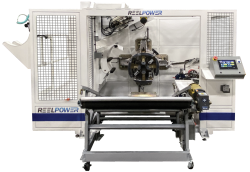

- 1, 2, 3, and 5 HP AC Vector Variable Speed Drive System to maintain line tension and automatically synchronize speed of coiler with speed of process line.A wide range of coiling equipment is available for winding material onto reels/ spools or onto coils (stretch wrapped or banded). Both on and off-line coilers areAutomatic Rewind Coiler comes out with higher coil production at lower cost, greater production flexibility and increase extrusion speed up to 100% and reduce labor cost up toSemiautomatic coilers are a low cost alternative to fully automatic equipment. These coilers wind the product as it emerges from the extrusion line automatically followingSemiautomatic coilers are a low cost alternative to fully automatic equipment. These coilers wind the product as it emerges from the extrusion line automatically followingHydraulic Power Unit for Reel Lifting and Pintle Positioning System and Inverted Auto Traverse with Adjustable Roller Guide Box for Under WindingSave warehouse space, improve internal logistics, and reduce shipping costs and product returns by producing coils of your HDPE, PP, PEX or PE-RT pipe products automatically fromThe Benefits of Reel Power Semi-Automatic Pipe Coiling System: Reduce CostsOnly one operator is required to oversee the operation of two or more machines. Where coilerCustom In-Line Dual Take-Up Coiling Machinery FEATURES:Model Shown ILHSS752-002 - Reference 38382 2 HP, 0-5 RPM, 230 VAC, 3 PH. AC Vector Precision Speed & TorqueReel Power Industrial’s custom ARC series single spindle film wrap coiler can be configured to work in-line. Corrugated coil will be film wrapped and auto ejected to customerLeaders with (PCT) Pipe Coil Technology Innovations Standard Features:Wide range of coil head adjustment Safe and ergonomic operation Automatic pipe layering AutomaticReduce Ovality and Achieve More Compact Coil Dimensions Low Ovality (LV) Technology was developed by and remains unique to Reel Power. It enables high density polyethylene pipe