We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

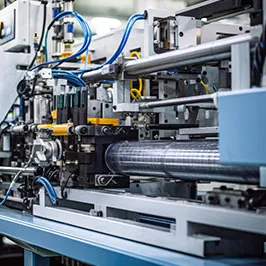

Downstream Extrusion Equipment

Reel Power offers game changing downstream extrusion equipment that provides accurate and precise pulling and cutting of pipes, profiles and tubes allowing you efficiency gains and unmatched final product quality.

- The downstream part of extrusion involves the (coating of metals), handling, cooling, cutting, and finishing of the extruded material once it exits the die. These operations are critical for ensuring that the final product meets the required specifications in terms of size, shape, surface quality, and performance.

- Aluminum Profiles: After metal extrusion, aluminum profiles may be plastic coated, cooled, stretched, and cut before they are surface finished.

For more inquires contact:

Rich Vester

Downstream Extrusion Sales Account Manager