We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Wire Manufacturing

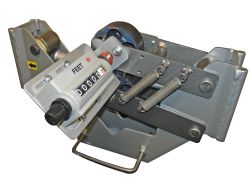

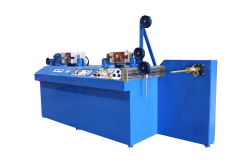

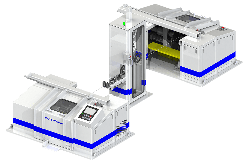

- Recommended for use with paying out material from supply reels. The HJP can improve the efficiency of your reel and cable handling operation. By utilizing a hydraulic jackPT series turntable is used for paying off wire, cable, hose, wire rope and other flexible products.1, 2, 3, and 5 HP AC Vector Variable Speed Drive System to maintain line tension and automatically synchronize speed of coiler with speed of process line.Heavy Duty Floor Mounted Shaftless Pay-Outs provide you with increased productivity, reduced processing time and fast, easy supply reel change-outs.Heavy duty floor mounted shaftless take-ups provide you with improved productivity, reducing processing time. Standard Speed Ranges 0-35 RPM or 0-70 RPM. Optional Dual Speed RangeReelpower Industrial Model 1704 measurer is designed to measure heavy and large diameter material such as Wire Rope and large diameter Cable. The pivot arms and springs keep$3,576.00The ReelPower Industrial Model 1700 material length measurer offers increased accuracy, durability and operator convenience. The ROM 1700 has a measuring head that literallyThe ReelPower Industrial 1700 series measurers are designed durable, easy to use, and highly accurate. Spring tension pinch roll design provides constant pressure on the materialStandard FeaturesLT 200 Series 1/64" to 2" Diameter material LT 400 Series 1/8" to 4" Diameter material Adjustable entrance & exit guide rollers - bothTAKE -UPRST3N 30” to 60” dia., 34” wide X 3,000 lbs. RST4N 30” to 60” dia., 36” wide X 4,000 lbs. RST5 36” to 72” dia., 45” wide X 5,000 lbs.RSP 20” to 48” dia., 36” wide X 2,500 lbs.RSP3N 20” to 54” dia., 54” wide X 3,000 lbs. RSP4N 30” to 60” dia., 38” wide X 4,000 lbs. RSP5 38” to 72”Standard FeaturesHD Frame with Bolt Down Tabs Variable Speed SCR Drive System 10” Dia. UHMW Guide Sheaves Manual Hydraulic Lift JackShafted and Shaftless Machines for Torque Synchronization. Manufactured to your specifications and Needs. Great for Extrusion/Pultrusion Applications.For pulling material from Pay-out equipment, or for in-process applications such as extruders. drawing lines, stranding lines, printers and automatic cut-to-length braiders.Reelpower Industrial PRR Series was created for use in extrusion, assembly and inspection processes or where minimum floor space usage is required. The PRR may be easily loadedAutomatic Cut to Length Machine - Automatic Cut to Length In-Line production and distribution machine. Designed specifically for production and distribution demands that requireWire Insulation Tester WIT 101 High Speed Re-Spooler: The Wire Insulation Tester (WIT ) is powered by a 1 HP variable speed drive system providing speeds up to 1,000 ft perStationary Reeling and Coiling Machinery Standard Reel Capacities: TAKE-UP RST3N 30” to 60” dia., 34” wide X 3,000 lbs.RST4N 30” to 60” dia., 36” wide X 4,000The Heavy Duty Coiler is to be used with Coil Steel, Rubber Belting, Sheet Tubing, Heavy Cable and other flexible material applications.Traversing Frame Take-Ups and Payoffs are someof the most advanced on the market today, now with capacities up to 250,000 pounds.Standard and custom systems are available forapplications in numerous industries from cablemanufacturing to umbilical, hose, tube, and pipe.Traversing Reel Take-ups and Payoffs are some of the most advanced on the market today. The units traverse the entire reel in front of the material line, creating an optimum layerReelPower Walk Through Shaftless Pay-Out are some of the most advanced on the market today,now it has some advanced features with 15,000 lb. capacity shaftless pay-Out.Bobbin Spooler & Shaftless Payout is one of the latest and best product with increased speed, it comes with shaftless RSP2 Payoff with advanced tension brake.The High Speed Take-ups and Payoffs meet the demand for faster speed, wire and cable manufacturing and rewind. The heavy duty fixed pintle design allows processing speeds up toPSTU and PSPO's are offered in capacities from 1,000 to 3,000 lbs. with reel sizes up to 60" in diameter. Drive options are AC, Mechanical and SCR.Reel changes don't have to mean lost productivity. Now you can run continuous production lines and control your Payouts and Take-ups with horizontal and vertical accumulators fromReelPower Industrial Cable new line of Automatic Dual Reel Take-Up systems offers high-speed material processing and durability for long operational life.The "RPO" series rotating cradle style payoffs are designed to neutralize back twisting in cabling lines. These systems work in conjunction with downstream pulling equipment suchSpiral Striping System is a practical approach to your wire identification requirements. Engineered to be the ultimate in high production wire coding systems, the WST-200 seriesReel Power Industrial has a wealth of experience with drives and controls - ranging from hydraulics, pneumatics, SCR DC, AC Vector to PC and PLC based control technology and theirThe Twinning & Quadding Equipment consist of on board capstan which pulls the wire at a constant speed to insure the proper lay length, and the tension take-up drive willEquipment BenefitsAutomatic Cut & Transfer Precision Military Winding Improved Production up to 1000 FPM Optional Automatic Stretch Wrap Lowest Maintenance No Belts,Small Caterpullar is used for pulling material from pay-out equipment, or for in process applications such as extruders, drawing lines,stranding lines,printers and automaticIn-Line shaftless automatic take-up machinery manufactured to synchronize with your process. It also comes with custom reel capacities designed as per your specification.The ACT System is highly flexible and reliable applicable to multiple products and applications. Now operating on and offline wire and cable, medical tubing andplasticTraversing Frame Take-Ups and Payoffs are some of the most advanced on the market today, now with capacities up to 100,000 pounds.Unit Features:Integrated safety featuresSafety Scanners Integrated Guarding Camera Integrated Safety Lock-Out systemSmart-phone compatibility IntegratedModel HDHSTU & HDHSPO Series of take-ups and pay-offs were developed for higher take-up and pay-off speed applications. A robust and compact design allows for minimum floorExtra Wide Gantry Takeups and Payoffs is one the outstanding product which comes with zero fleeting angle in your Line and also comes with extra wide telescoping frame to fitBinder BH5-S comes with custom sized to fit your needs and it allows shaft to ride on roller bearings.ILHSS Series HD Automatic Coiling Machine comes with adjustable cable tensioner for providing back tension and free standing heavy duty out of material limit, allows machine toSemiautomatic coilers are a low cost alternative to fully automatic equipment. These coilers wind the product as it emerges from the extrusion line automatically followingBobbin Spooler System - 3500 FPMNEW DESIGN!Fully automated patent pending split style flooding adjustable coiling head holdsstem pack in place to reduce changeover• Cutter/Coiler/Binder • Cuts Wire to Desired Length • Binds Coil in Two Places • Custom Tail Lengths for TerminationAutomatic Coiler • Allen Bradley PLC • Red Lion HMI • Automatic Feed • Automatic Cutter • Automatic Coiler • Automatic Bander • Automatic EjectFor High Production Environments CHPM Series Precision-machined, Adjustable Coiling Heads offer: • Machined components offering close tolerances • Four & five arm1. The operator inserts an axle onto the reel with the proper reel adapter bushing.2. Tilt the cart onto the wheels and maneuver the unit forward into the reeluntil the reel axleNK Series: Take-Up Reeling Machine and Coiling Machine comes with powered hydraulic control to raise and lower the reel automatically